Spec:

feature

1. Ultra-high capacity and long-term welding

Ultra-high current output: The maximum current can reach 32000A (NT-IN32K444 at 400V), which is enough to handle the most demanding welding tasks.

Ultra-long welding time: up to 5 seconds of welding time, suitable for welding of various thick and heavy materials.

2. Precise control and diverse functions

127 STEP arbitrary waveform: Provides highly flexible waveform settings to meet various welding process needs.

8-phase pulsation operation: By precisely controlling the rising and falling slopes, stable and reliable welding quality is achieved.

Welding stops changing below 1ms: ensuring high precision and stability of the welding process.

Multiple control modes: Provides multiple control modes such as constant current and constant voltage to meet different application scenarios.

Welding monitoring function: Built-in multiple monitoring functions such as current, voltage, power, etc., and provides real-time data display and analysis, which helps optimize welding parameters.

Welding waveform display: Through the intuitive waveform display, it is convenient for users to quickly grasp the welding status and improve work efficiency.

3. Automation and intelligence

Support automated machines: Through input control mode, it can be easily integrated into automated production lines.

Remote control: The program box supports remote control, improving the flexibility of the system.

Compensation function during welding: The output parameters can be adjusted according to external signals to achieve more accurate welding.

Content:

AVIO NRW-IN900P high-capacity splicing power supply brings revolutionary changes to the splicing industry with its advantages of ultra-high capacity, long-lasting splicing, precise control, diverse functions, automation and intelligence. Whether it is in the automotive, electronics, or heavy industry fields, NRW-IN900P can provide reliable and efficient welding solutions.

SPEC

| Item | NRW-IN900P |

|---|---|

| Control Frequency | Selectable from 2kHz、4kHz、5kHz (Select for each PRG No.) |

| Control Mode | Primary current peak value control, Primary current average value control, Secondary current avarage value control, Secondary voltage avarage value control, Secondary power avarage value control, Fixed pulse width control. |

| Maximum Welding Current | 900A(Duty Cycle 5%) |

| Range of Timer Setting | Nomal mode: 0.0-5000.0ms(Total of UP TIME、WELD TIME、DOWN TIME、COOL TIME) Pulsasion mode: 0.0-24000.0ms(Total of PULSE TIME、COOL TIME) |

| Number of Conditions | Normal mode: 255 Pulsasion mode: 15 |

| Welding Waveform Setting | Normal mode: 3-phase(slope、weld、cool)、free style(Max. 127 step、8-phase) Pulsasion mode: (Max. 120 wave、10000 pulse、8-phase) Analog input control mode: (8-phase) |

| User Interface(Setting Tool) | Program box |

| Monitoring Function | Average value/peas value monitor of current, voltage, power resistance respectively. Pulse width, welding time monitor, phase monitor, Source voltage monitor. Waveform display |

| Cooling Method | Water cooling (Volume of water 3.0ℓ/min) |

| Interface | Ethernet |

| Power Source | 220V:3φ AC200-240V±10% 50/60Hz、400V:3φ AC380-480V±10% 50/60Hz |

| Dimensions(mm) | W250×D651×H428(Excluding protrusions) |

| Weight | 30.4kg |

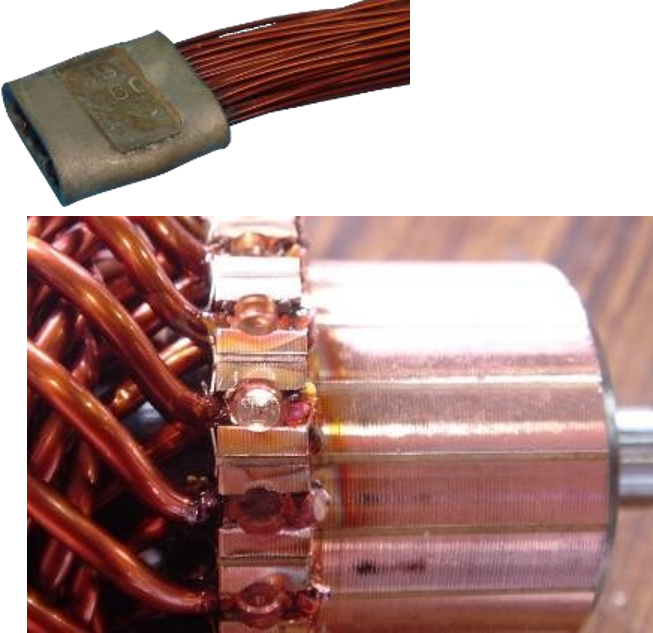

| Welding Transformer |

NT-IN32K444 |

| Item | NT-IN32K444 | |

|---|---|---|

| Power Source | 220V | 400V |

| Maximam Welding Current | 19800A(Duty Cycle 5%) | 32000A(Duty Cycle 5%) |

| Rated Capacity (Duty Cycle 50%) | 89 kVA | 130 kVA |

| Primary Input Voltage | 300V | 600V |

| Secondary Open Circuit Voltage | 14.1V | 12.9V |

| Transformer Turns Ratio | 22:1 | 44:1 |

| Input Frequency | 2kHz/4kHz/5kHz | |

| Cooling Method | Water Cooling 3.0ℓ/min | |

| Dimensions(mm) | W280×D475×H330(Excluding Protrusions) | |

| Weight | 43.2kg | |