Spec:

Feature

・Switchable Inverter Frequency

The model standard operating frequency is 2000Hz (energization time resolution 0.5ms) with the option to switch to 4000Hz (energization time resolution 0.25ms) or 5000Hz (energization time resolution 0.2ms). The optimal frequency can be selected that realizes high-quality welding with less current ripple based on the workpiece.

・127-Step Free Style Profile

The operator has the option to set "SLOPE", "WELD" and "COOL" arbitrarily with up to 127 steps as a standard feature. Multi-stage slope welding and other multi-stage welding, such as pulse 63-stage welding, are possible. This feature allows high quality joining by precise heat input control for both resistance weld and resistance heat applications.

・1 ms Variable Weld Stop Control

Reduce the margin of error in the workpiece displacement.

・Multi-Transformer Support

The Trans Switch option allows the user to connect up to 4 transformers to one welding controller power supply using a transformer switch. With this option multiple welding processes can be implemented using a single welding controller and multiple transformers.

This provides the client with maximum flexibility while maintaining production capacity and capabilities. In addition, equipment installation costs can be reduced and the load on power equipment in the factory can be reduced (load leveling).

Simultaneous pressurization, sequential welding and installation of equipment for multiple processes are also possible. In addition, the Transformer Relay Box option allows the user to connect to existing transformer models.

・Welding Parameter Compensation

To perform optimum welding, the standard programmed weld parameters are fine tune adjusted based on changes in room and electrode temperatures. The “base or typical” welding parameters are stored for each program number. During the actual weld, parameters are compensated according to changes in room temperature and electrode temperature as monitored by the system. This allows for more consistent bonds that are not, or at least minimally, affected by changes in the ambient environment.

・Dust-Proof, Reinforced Structure

Automated systems integration is easier using the model program box which includes remote control.

・Multiple Power Supply Capability

The model can operate on three-phase power supply from AC200 to 480V without changing or modifying the standard system welding power supply.

Content:

High-performance welding power source that pursues convenience

This welding power source is a high-performance high-frequency welding power source with high precision control. Equipped with arbitrarily selectable frequency,

127-segment power supply function enables high-reliability welding in various situations.

Moreover, the separate operation control box method improves the convenience of automatic equipment configuration of the welding power source.

It is the latest welding power source that is sturdy and reliable and suitable for automated equipment.

SAMPLE

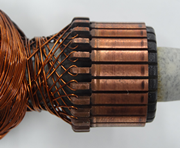

整流子×マグネットワイヤ 銅端子×マグネットワイヤ 圧着端子×マグネットワイヤ

漆包線 x 銅排(馬達) 漆包線 x 銅端子 漆包線 x 端子

多路分歧焊接變壓器系統

| MODEL | NRW-IN400P |

| TR | NT-IN8444A |

| CURRENT | 8000A |

| Hz | 5kHz |

| TIME | Air cooling 5% (1000ms) |

| 電流、電壓、功率、電阻、監測功能 | Average/peak of current, voltage, power, resistance and pulse width |

| WARE | N/A |

| CH | 255 Conditions |

| PORT | Ethernet, CF card |

| COOL | Aircooling |

| POWER | 3 phaseAC 200 to 480V 10% |

| SIZE.Weight | W186 x D490 x 279mm |

| 18kg |