Spec:

Product Features & Advantages

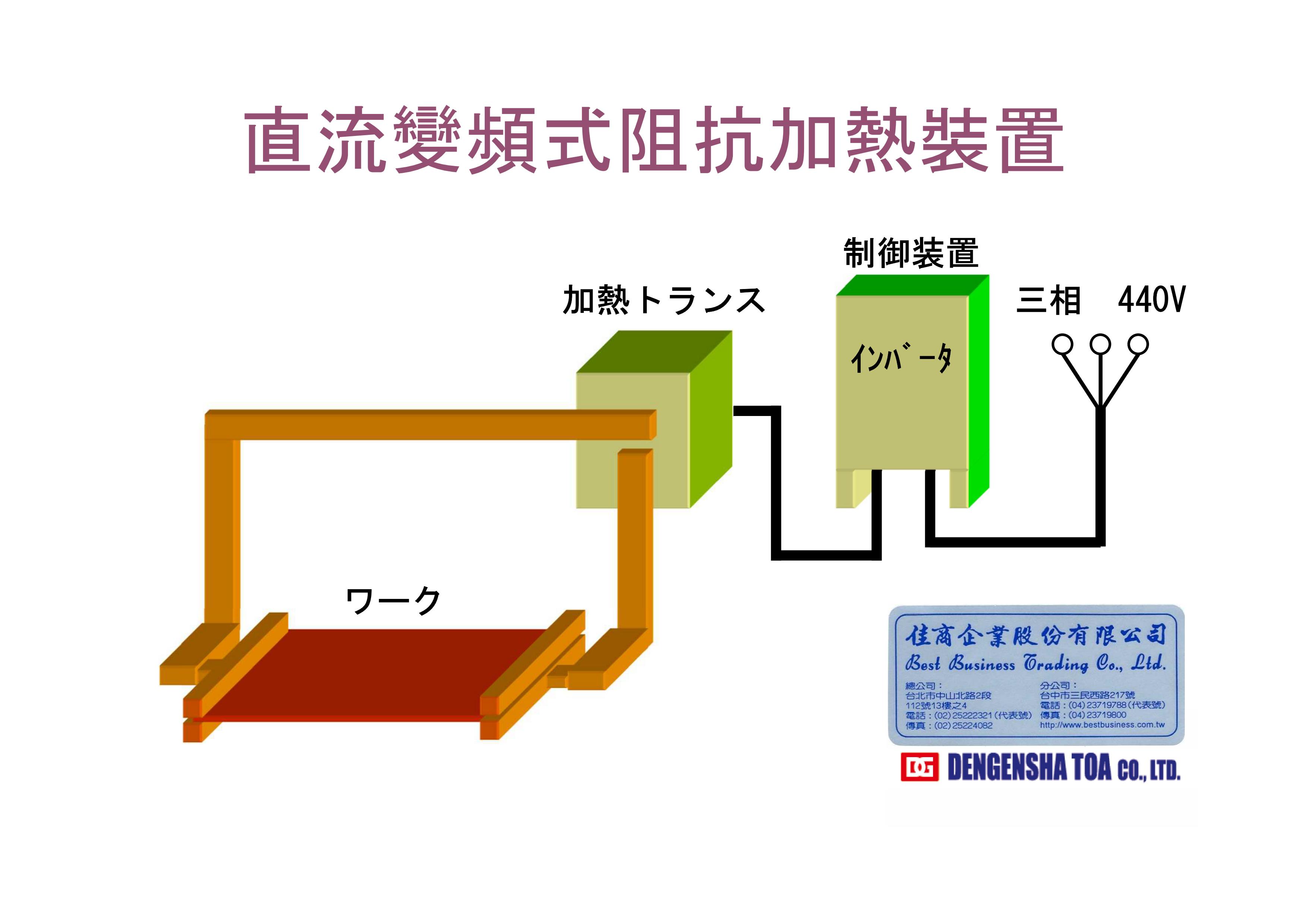

- High-Efficiency and Energy-Saving Heating Principle: The core of this device is DC resistance heating technology. It heats steel materials by passing current directly through them, converting electricity into heat with minimal waste. This method is nearly twice as energy-efficient as high-frequency induction heating, significantly reducing energy consumption and production costs. Additionally, the three-phase input design means the equipment capacity is only one-third of a single-phase AC system, saving valuable floor space.

- Increased Productivity and Precise Control: The DC inverter design allows for rapid heat treatment, which significantly boosts overall production efficiency. This technology from Densha enables up to 255 current condition switches during heating, along with analog input support, for extremely precise temperature control. This is crucial for processes requiring high-precision heat treatment, such as steel plate heating or forging part heating.

Content:

Applications and Optional Accessories

- Primary Applications: This technology is widely used for heat treatment of metal parts, especially for automotive components. Common applications include the heat treatment of stabilizer bars, springs, and hot stamping materials, as well as pre-heating for forging.

- Flexible Optional Accessories: To provide a more complete solution, the device offers several optional accessories:

- Touchscreen heating control system: Provides an intuitive and convenient user interface.

- Primary circuit breaker: Ensures safe operation of the equipment.

- Workpiece jigs and secondary cables: Can be customized for different shapes and sizes to ensure stable and efficient DC resistance heating.