Spec:

CO2 Laser Processing1 Does not damage the metal conductor

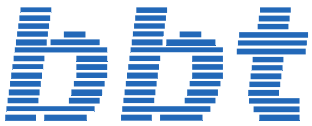

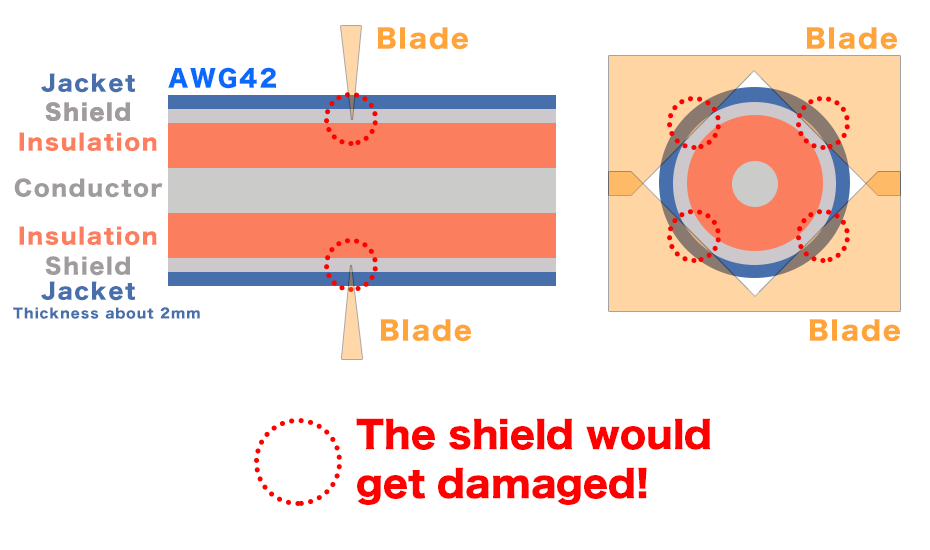

In the case of conventional mechanical strippers using a blade, the shield wire and core wire just below the insulation would get damaged.

Since a CO2 laser can selectively cut only the resin layer, the shield wire and core wire are not damaged.

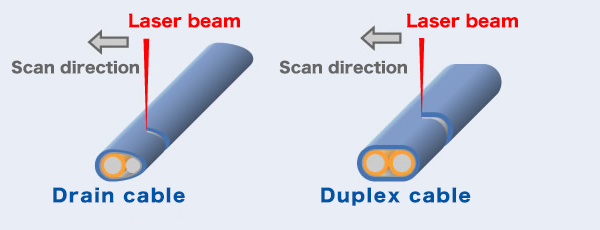

2 Non-contact processing that is not restricted by the shape of the workpiece

Cables shown below, which are difficult to cut with a blade, can also be cut without any problem. Since this is non-contact processing, it is not restricted by the cross-sectional shape of the workpiece.

3 No change in processing accuracy by wearout of components

Because there is almost no effect on the processing accuracy by wearing of components as in the case of a blade, a constant processing accuracy can be maintained over a long period of time.

Dedicated Cable Stripping Machine

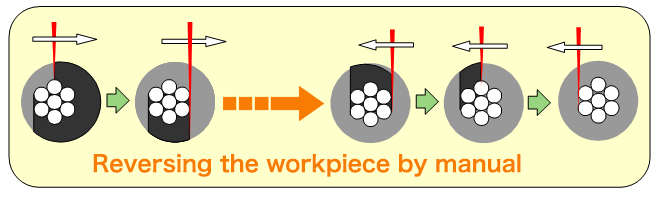

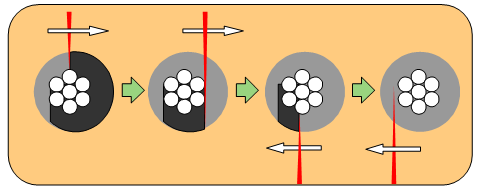

1 Workpiece need not be reversed

In a simple machine using a laser marker, since laser irradiation is performed from a single direction, the deviation of the upper and lower processing positions caused by the mechanical wobble during reversal of the workpiece is a problem.

Because this machine supports upper and lower 2-way irradiation, the workpiece need not be reversed. Due to a simple stage structure and workpiece fixing method where no wobbling is present, both high operability and high-accuracy processing have been realized.

<示意圖>

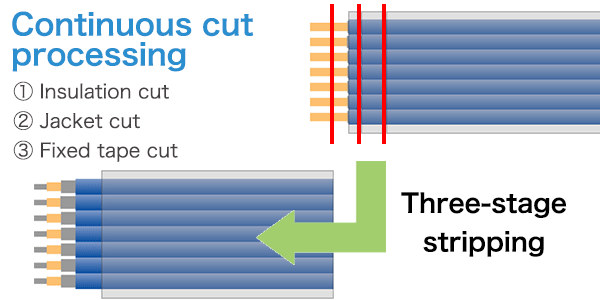

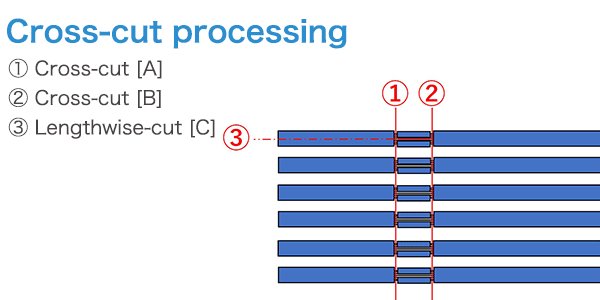

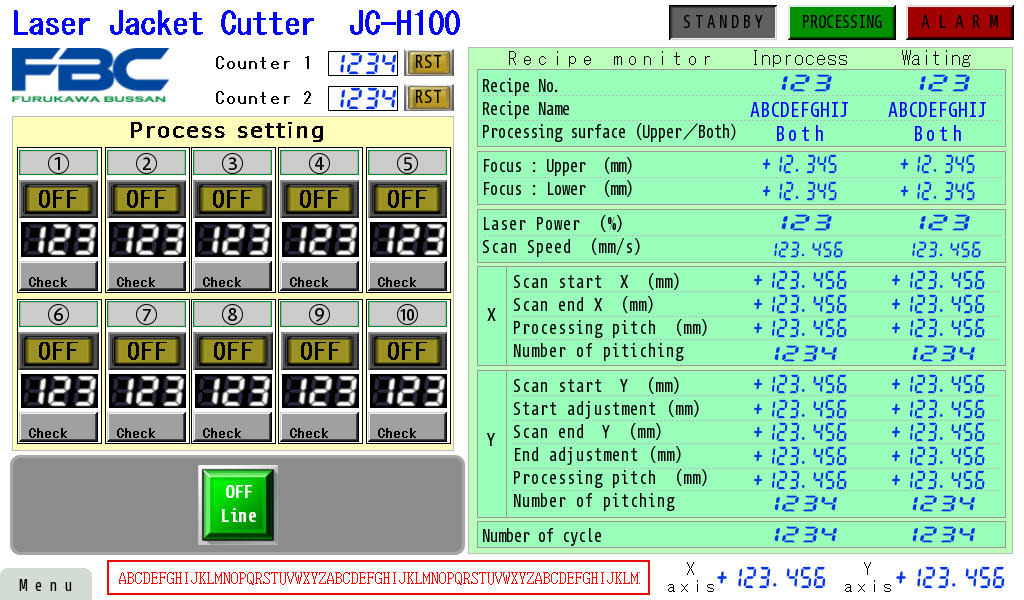

2 A wide range of processing can be performed through a simple operation

The simple operation involves only setting the workpiece and pressing the start button.

By combining together the "Laser processing conditions" and "Processing position conditions", changes in processing conditions by process and by product, and continuous processing of several locations can be performed through a simple operation of pressing the recipe selection button.

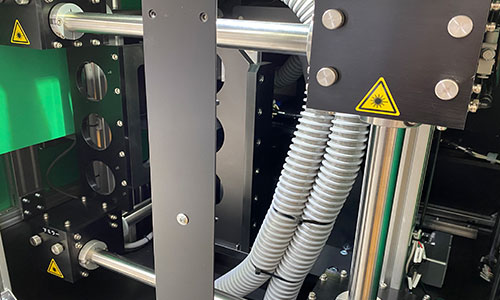

3 Simple maintenance

When processing is performed using laser, there is a problem of decline in output because the flue dust generated at the time of processing the coating adheres on to the lens and mirror. In the latest model, the mirrors and lenses inside the machine are housed in separate optical boxes. Since each optical box is connected by a pipe, dust and smoke can be prevented from entering from the outside, so the machine can be used over a long period of time without having to replace the consumable parts.

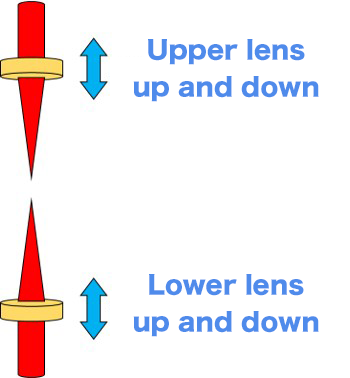

4 Numerical control of focus position adjustment

Numerical control of the focus position can be possible by a precision motor. The recipe can be registered according to the wire type and wire diameter, so you can only select the recipe to change the setup for small quantity and many kinds of products with different wire diameters! It is highly reproducible and there is no downtime during setup changes. Ideal to develop prototypes!

Content:

| Item | JC-H100 | JC-30XS | JC-30XL | |

|---|---|---|---|---|

| Laser oscillator | Type | CO2 laser | ||

| Wavelength | 10.6µm | |||

| Output power | 30W or above (CW Maximum rated output) | |||

| Power stability | ±5% or less | |||

| Beam size | 150µm or less (Theoretical focusing diameter) | |||

| Head scanning | Effective processing range | (X) 100mm (Y) 100mm |

- | - |

| Maximum scanning speed | (X) 300mm/s (Y) 100mm/s |

- | - | |

| Stage scanning | Effective processing range | - | 85mm | 300mm |

| Maximum scanning speed | - | (Y) 300mm/s | (Y) 300mm/s | |

| Processing position setting stroke | - | 30mm (Electric) | ||

| Optical unit | Focus adjustment mechanism (2 Way) | Electric | Manual | Manual |

| Stage accuracy stage resolution | Processing position accuracy | Less than 0.05mm | ||

| Resolution | 0.01mm | |||

| Utility | Power supply | Single phase 50/60Hz 100~230V (1kVA) |

Single phase 50/60Hz 100~230V (800VA) |

|

| Air supply | 0.4Mpa or above | |||

| Exhaust connection | ≧3.5m3/min (φ50mm Exhaust flange) | |||

| Processing range | (Indication) | Φ8mm ~ AWG52 coaxial cable ※Depends on the jacket material and thickness |

||

| Exeternal communication | Only for JC-H100 | FBC standard external communication by CC-Link | ||