Spec:

characteristic:

1. No wearing parts: Semiconductor laser is a light source technology with many advantages. First of all, there are no wearing parts in the design of semiconductor lasers, which makes them more reliable during operation and reduces maintenance requirements. This characteristic makes semiconductor lasers excellent in a variety of applications, especially in environments that require high stability.

2. Miniaturized structure: Semiconductor lasers have a miniaturized structure, which allows them to be easily integrated into various devices, ranging from small electronic products to large industrial machines. This miniaturization advantage makes semiconductor lasers more and more popular in modern technology.

3. Long service life: The service life of conductor lasers is long, usually reaching tens of thousands of hours, which means that users can enjoy stable performance for a longer period of time without frequent replacement of equipment, thus reducing the cost of long-term use.

4. High electro-optical conversion efficiency: Semiconductor lasers have high electro-optical conversion efficiency and can effectively convert electrical energy into light energy. This not only improves energy utilization, but also reduces operating costs and also contributes to environmental protection.

5. Uniform beam energy distribution: The beam energy of semiconductor lasers is evenly distributed, which is particularly important for precision processing, medical applications, lighting and other fields to ensure consistent results in various operations.

Content:

application:

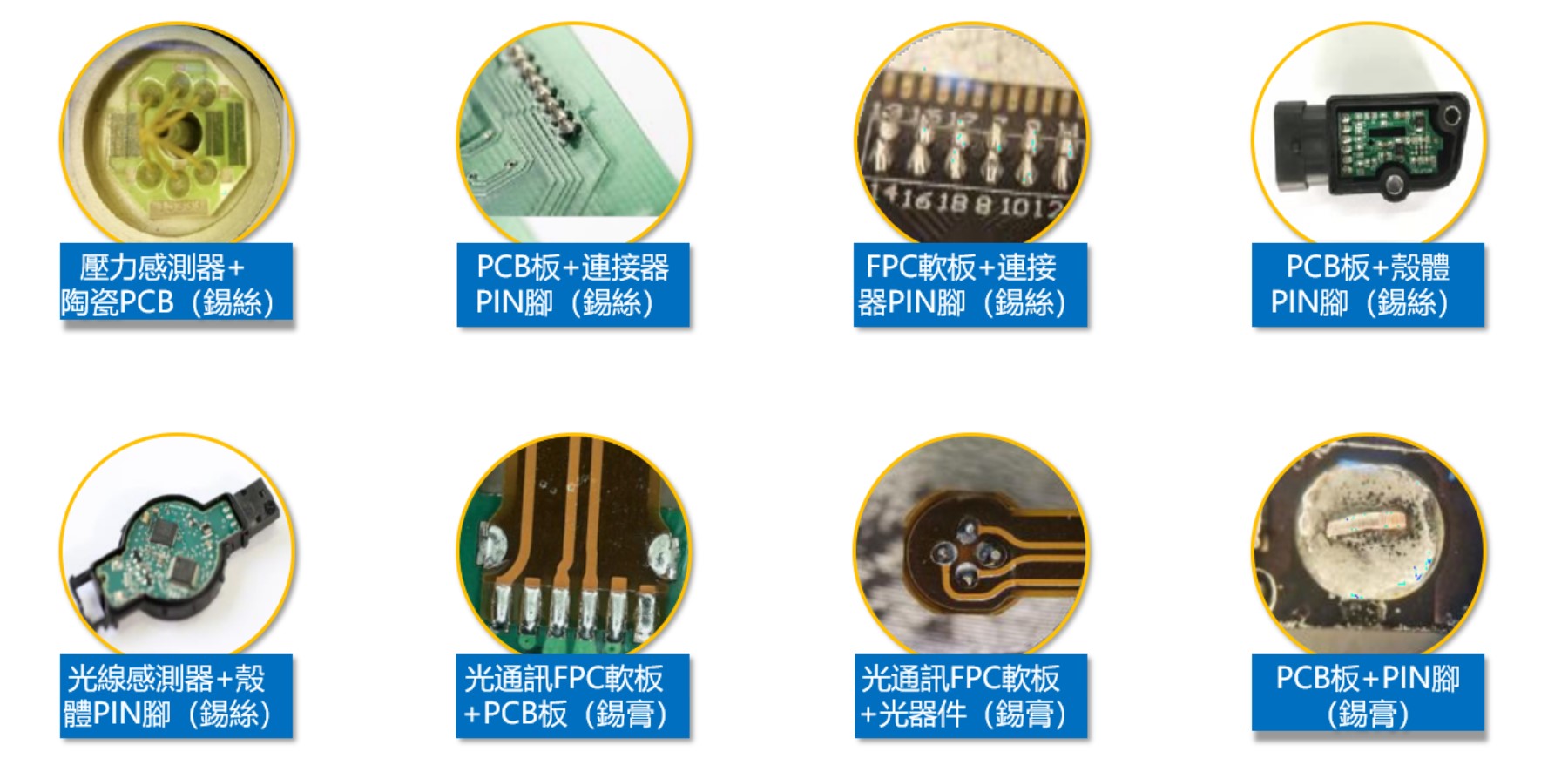

Electronic Equipment: Widely used for soldering tiny components such as integrated circuits, capacitors and resistors.

Automotive industry: Achieve high-precision welding in the assembly of electrical systems and electronic modules.

Medical equipment: used for welding various medical devices and implants to ensure their stability and reliability.

Optical components: Provide high-precision connections in the assembly of optical fibers and optical equipment.

Microelectromechanical systems (MEMS): used for the assembly of MEMS devices to ensure the integrity of their tiny structures.

This technology is widely favored for its high efficiency and low thermal impact, making it particularly suitable for applications requiring high precision.