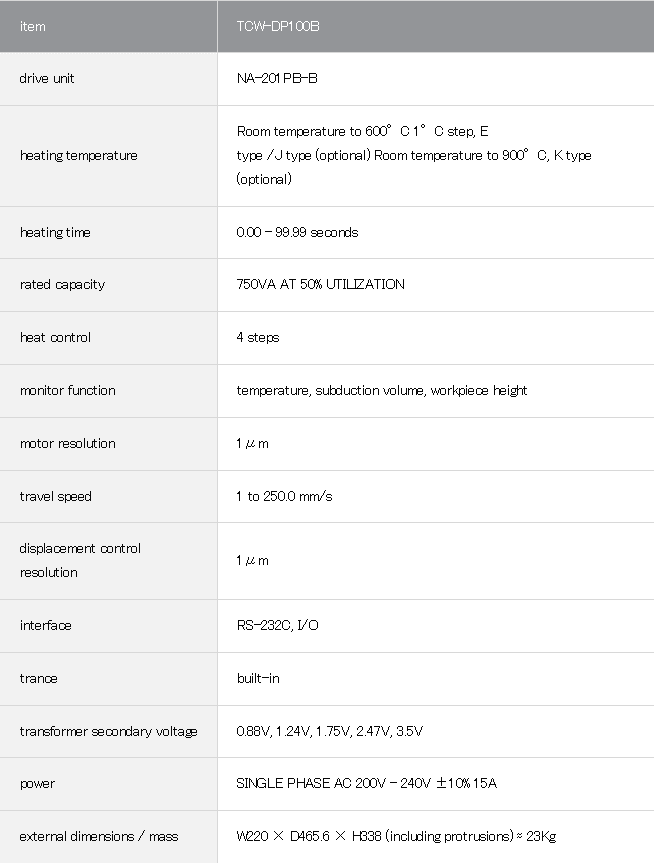

Spec:

ultimate lipro control! simultaneous control of the temperature and displacement of the heater tip!

- high-precision

displacement control the subduction amount is controlled by the displacement feedback with a resolution of 1 μm, and a uniform penetration amount is realized. - abundant monitoring functions (temperature and displacement)

- Digital temperature

control The digital PID control system realizes high-speed, high-precision temperature profiles, and supports fine lines and small workpieces. - release

function after heat, the thickness of the solder between the workpieces is ensured. - 4-stage

heating realizes a variety of temperature profiles to support diversified applications. - built-in electric slider control

- User

interface RS-232C&O is standard, and it can be easily connected to external devices such as mounting on automatic machines.

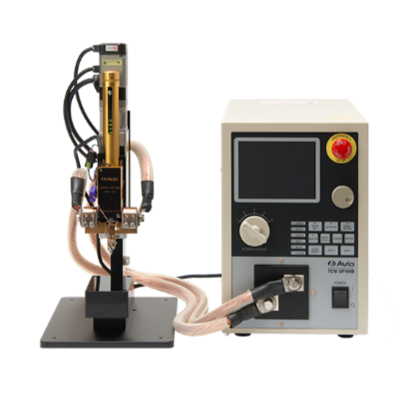

Content:

application

Electronic component assembly: widely used in soldering of circuit boards, especially in surface mount technology (SMT), to ensure stable connection of components.

Medical Devices: Used to produce various medical devices, such as sensors and surgical instruments, ensuring precision and safety.

Optoelectronic products: In the manufacturing of solar cells and LED lamps, hot pressure welding is used to join different materials to improve efficiency and performance.

Plastic Welding: Used for joining various plastic parts, especially in packaging and container manufacturing, to provide sealing and stability.