Spec:

characteristic:

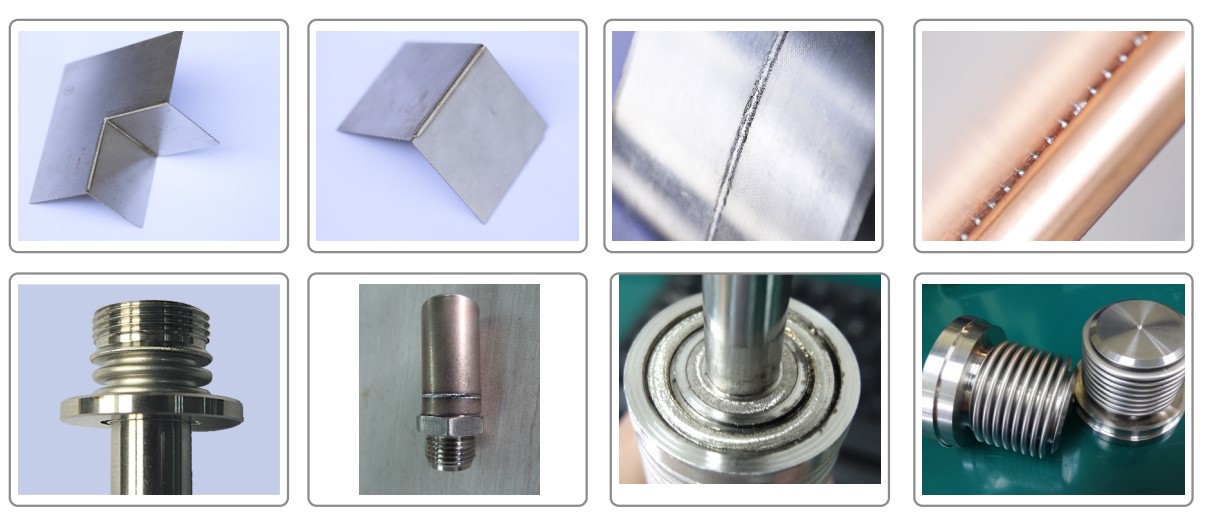

1.Small heat-affected area and small deformation during the welding process: YAG laser welding machine is an efficient and precise welding equipment with many advantages. First of all, during the welding process, the YAG laser welding machine has a small heat-affected area and small deformation, which means that during the welding process, the heat impact of the workpiece can be effectively controlled, thereby reducing deformation and maintaining the original shape and size of the workpiece. Accuracy.

2.Can perform spot welding, stack welding, butt welding and seal welding on workpieces: YAG laser welding machine can flexibly respond to various welding needs and can perform spot welding, stack welding, butt welding and seal welding on workpieces. , to meet the needs of different industries and applications.

3.The weld seam is smooth and beautiful, and no further processing is required after welding, or only simple processing is required: The weld seam of this equipment is flat and beautiful, and no further processing is required after welding, or only simple processing is required. This not only improves production efficiency, but also reduces subsequent costs. The cost of processing makes the products more in line with high-standard quality requirements.

4.Realize energy spectroscopy, time spectroscopy, and high-speed spectroscopy: The YAG laser welding machine also has the functions of energy spectroscopy, time spectroscopy, and high-speed spectroscopy, which allows it to more accurately control the energy output during the welding process, further improving the welding quality and efficiency. .

5.Real-time energy negative feedback laser energy control technology to achieve consistent welding results from beginning to end: This model has real-time energy negative feedback laser energy control technology to achieve consistent welding results from beginning to end, which is required It is especially important for high-end industrial applications to ensure that every solder joint meets the expected standards.

.jpeg)

Content:

application:

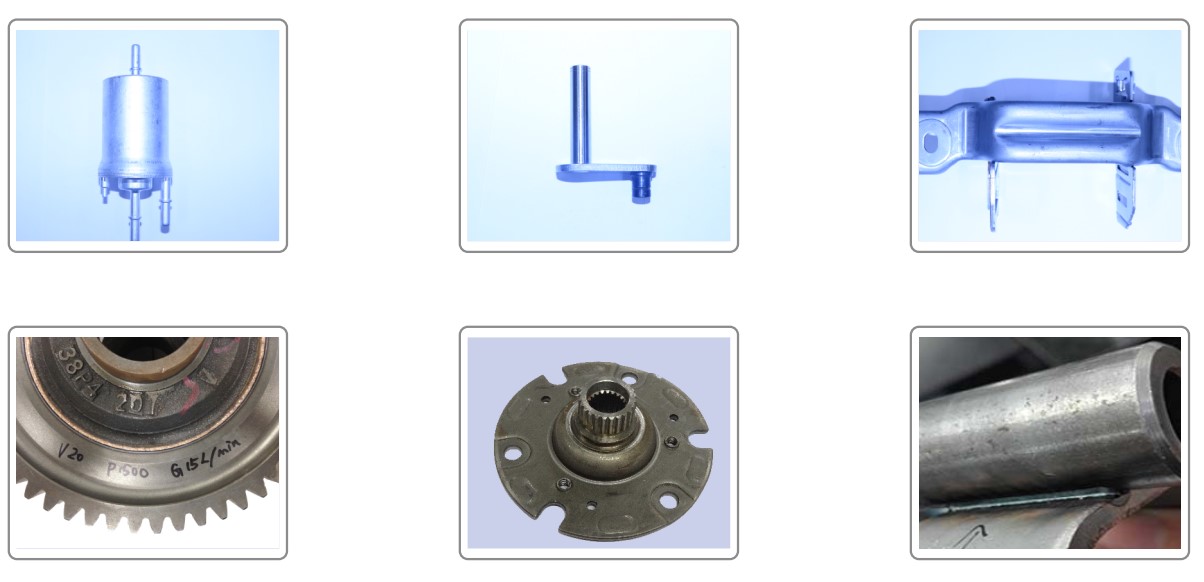

1. Automobile manufacturing: used for welding body structures, chassis and battery modules to provide high-strength connections.

2. Aerospace: In the welding of high-performance materials, ensure the safety and reliability of the structure.

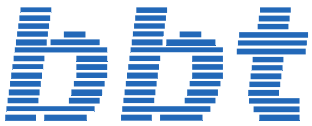

3. Electronic products: Suitable for welding of small electronic components, such as circuit boards and sensors.

4. Medical equipment: used for welding precision medical devices and implants to ensure their function and safety.

5. Metal processing: widely used in welding of various metal materials, including stainless steel, aluminum alloy, etc.

YAG laser welding has high energy density and excellent welding quality, and is suitable for applications requiring high precision and high strength.

電池應用

光通訊

汽車

家電五金