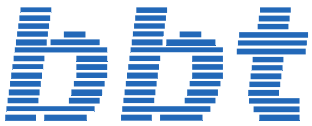

Spec:

characteristic:

1. Miniaturization, precision, and high integration: With its compact design, UW fiber laser welding machine can achieve high-efficiency welding in a limited space and is suitable for various production environments.

2. Calibration-free, maintenance-free, and high stability: This equipment not only simplifies the operating process, but also reduces maintenance requirements, ensures long-term operation stability, and significantly reduces labor costs and time loss.

3. Adapt to harsh working environments: It shows extremely high tolerance when faced with challenges such as dust, vibration, impact, temperature and humidity changes, and can continue to operate under various harsh working conditions to ensure welding quality.

4. High electro-optical efficiency: The comprehensive electro-optical efficiency of this model is as high as more than 20%, which means that it can significantly save power consumption during welding operations, thereby reducing operating costs and improving production efficiency.

5. Diverse specification selection: UW fiber laser welding machine provides a variety of power options from 500W to 6000W, which can meet different welding needs, whether it is fine welding or high-power welding, it can be easily handled.

6. Advanced control system: Equipped with an advanced digital control system to achieve precise welding parameter adjustment, and can perform intelligent settings according to different materials and welding requirements to improve welding flexibility and accuracy.

7. Environmentally friendly design: Environmental protection factors are considered in the design, reducing harmful emissions and meeting the needs of modern industry for sustainable development.

8. Humanized operation interface: With an intuitive and easy-to-use operation interface, even novices can get started quickly, reducing training time and improving work efficiency.

Content:

application:

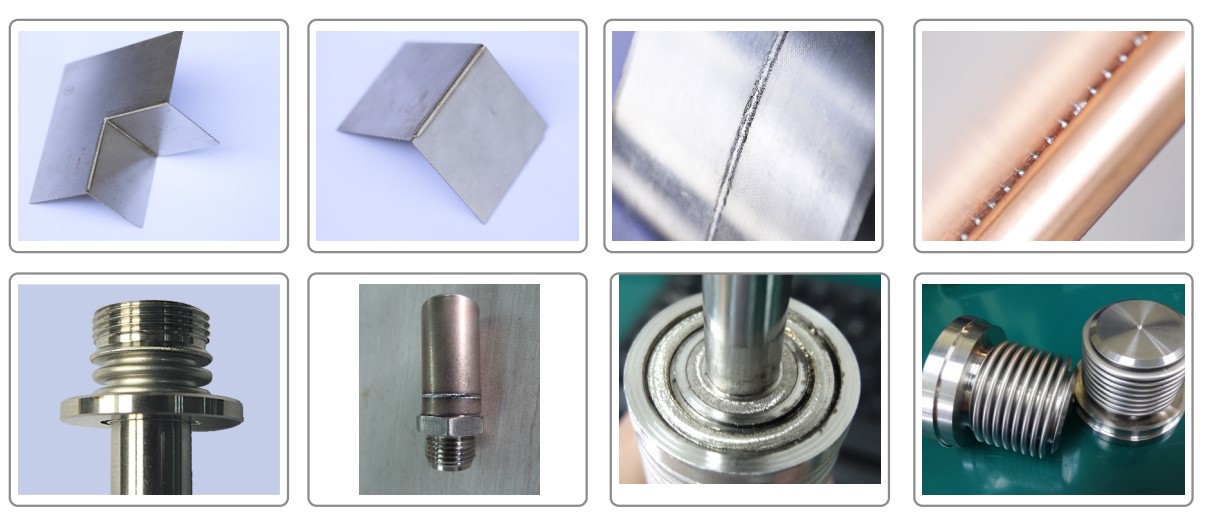

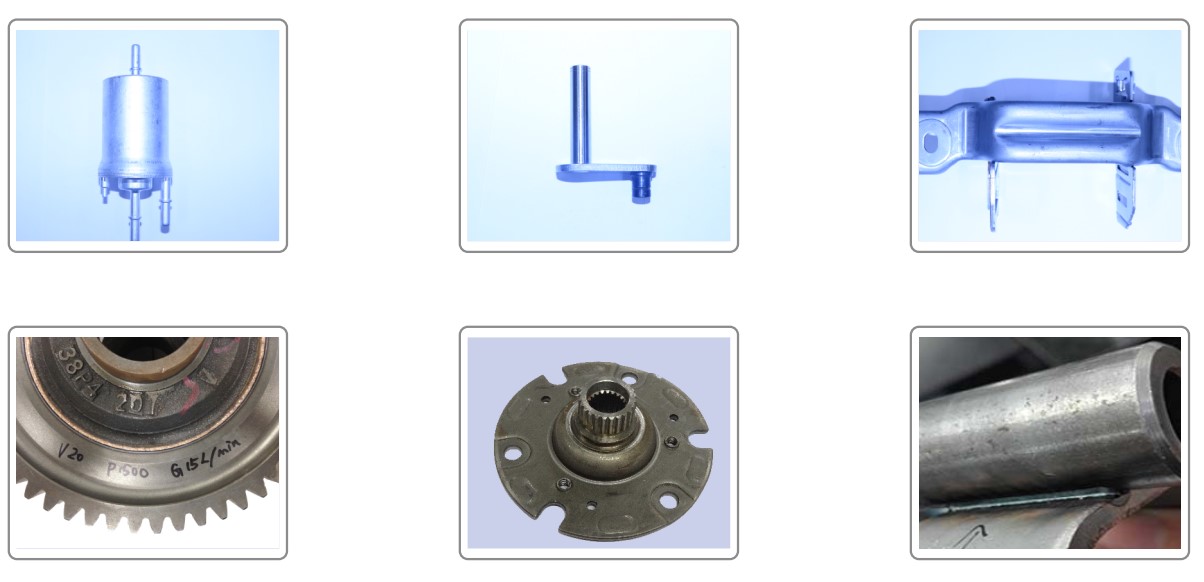

1.Automobile manufacturing: used for welding body, chassis and other components to improve welding strength and precision.

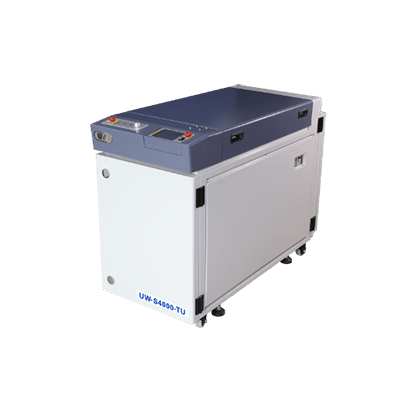

2.Electronic products: suitable for welding of small electronic components, such as mobile phones, computers, etc.

3.Aerospace: Precision welding under lightweight and high strength requirements.

4.Medical Devices: Used to manufacture high-precision medical devices such as surgical tools and implants.

5.Metal processing: widely used in the splicing and repair of metal parts.

Fiber laser welding technology has the advantages of small thermal impact, fast welding speed and strong adaptability. It is one of the important technologies in modern manufacturing industry.

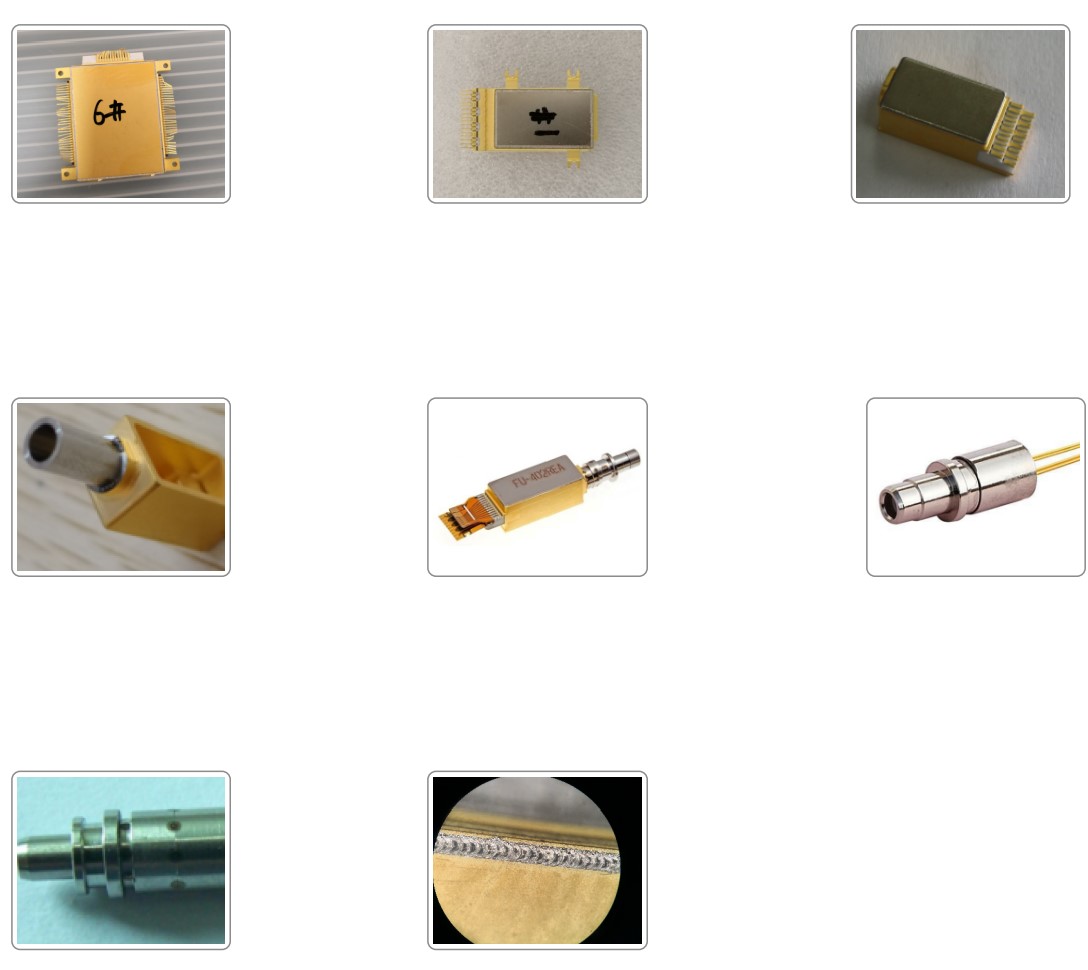

電池應用

光通訊

汽車

家電五金