Spec:

feature

1. Can provide stable energy

Our unique inverter control technology enables us to provide high precision and stable welding current.

2. Provide welding quality with less thermal impact

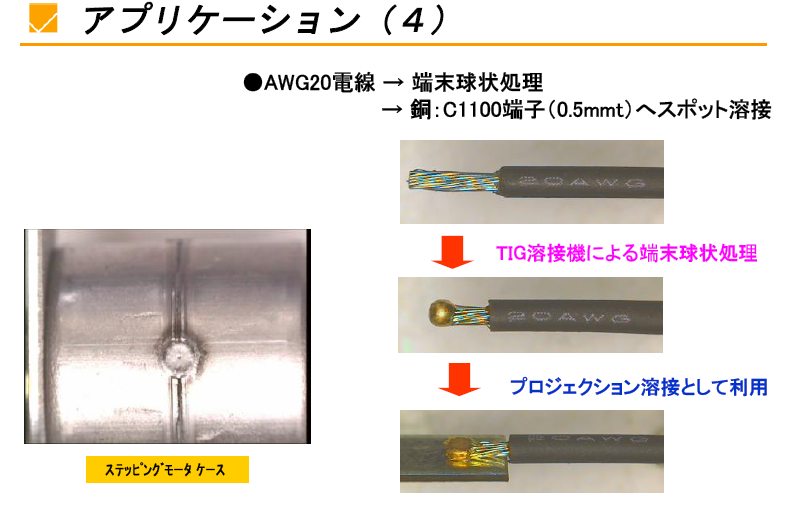

Conventional arc welding controls time in 0.1-second increments, but "ITEK-1050V/1300V" can be set in 1/10,000-second increments (99.9 milliseconds or less).

This enables arc welding of precision parts and tiny parts that were previously impossible.

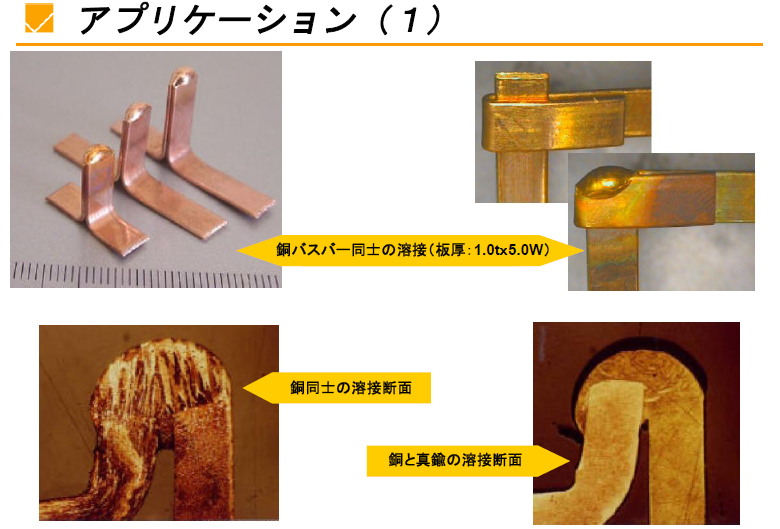

3. Can weld high melting point metals and dissimilar metals

Unlike diffusion joining methods such as resistance welding and ultrasonic welding, dissimilar metals can be joined through fusion welding.

4. Easily manage welding conditions through digital settings

Digital setting of welding current value and power-on time. Multiple optimal welding conditions can also be stored.

It can display the actual average welding current value and judge the upper and lower limits.

5. Through inverter control, significant miniaturization and weight reduction are achieved

Approximately 70% smaller and 50% lighter than the previous model, it is significantly smaller and lighter.

6. The welding quality can be judged through current monitoring and power-on time monitoring.

By setting the upper and lower limits of the current monitor and power-on time monitor, the quality of each weld can be judged.

Content:

.png)

SPEC

|

MODEL |

1050V |

1300V |

|

INPUT POWER |

單相AC200V±15%(50/60Hz) |

|

|

OUTPUT A. |

50A |

300A |

|

KVA |

2kVA |

6Kva |

|

MAX CH. |

16CH |

|

|

COOLING |

AIR |

|

|

CURRENT ADJ. |

0.0A~50.0A: 0.1A |

0.0A~300.0A(0.0~99.9A): 0.1A 100A~300A:1A |

|

RANGE |

PEAK Ah1: 1.0A~50.0A |

UP A:10A~300A WELD A:10A~300A DOWN A:10A~300A |

|

SIZE |

170W x 295H x 440D |

210W x 385H x 560D |

|

WEIGHT |

12kg |

30kg |